Gear Couplings

Horsburgh & Scott engineers the toughest, most reliable gear couplings to ensure uninterrupted power transmission and longevity for heavy-duty industrial equipment.

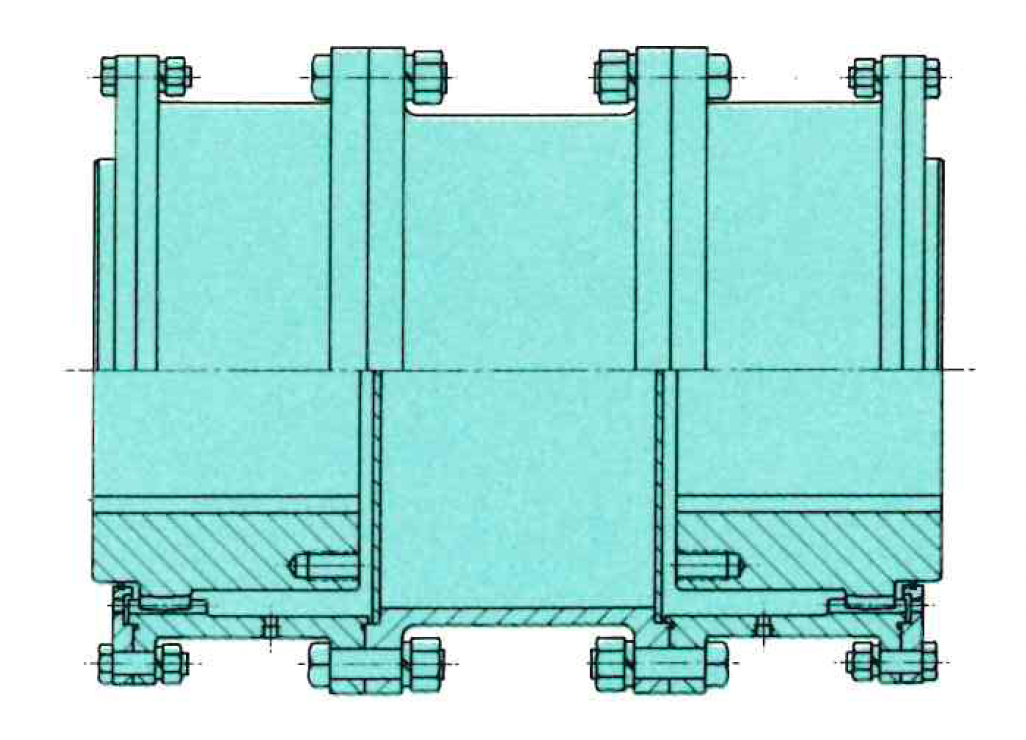

Rugged Large-Bore Gear Couplings for Heavy Industry

Horsburgh & Scott large-bore gear couplings provide reliable transmission of high torques at low speeds, plus maximum misalignment capability between driving and driven shafts.

Each is engineered, built and quality checked to ensure long coupling life, trouble-free operation.

Find Sales Rep or call (216)431-3900

Gear Teeth

Flexible hub teeth, crown hobbed with 20° pressure angle full depth teeth, provide high capacity under misalignment conditions.

Three surfaces (tip, flank, and root) are crowned. Internal teeth are generated on precision gear shaping machines.

Materials

Hubs and sleeves are machined from forged medium carbon steel as standard. Heat treated alloy steel can be furnished as an option.

Fasteners

All cap screws are Grade 5 material. Center flange utilizes machined fitted bolts.

Seals

“O” ring seals at center flange, end flanges, and hub.

Lubrication

Two lubrication plugs @ 180° are provided in each flex sleeve. Grease purge holes in end plates allow complete lubrication.

Interchangeability

Horsburgh & Scott coupling halves can be manufactured to be interchangeable with other industry standard couplings.

Ratings and Size Selections

Tabulation on facing page provides mechanical ratings for all sizes in HP per 100 RPM.

When selecting a coupling, it is necessary to apply a service factor to adjust the rating for the type of application and duty cycle. lndustry standard service factors may be used, or consult H&S for recommendations.