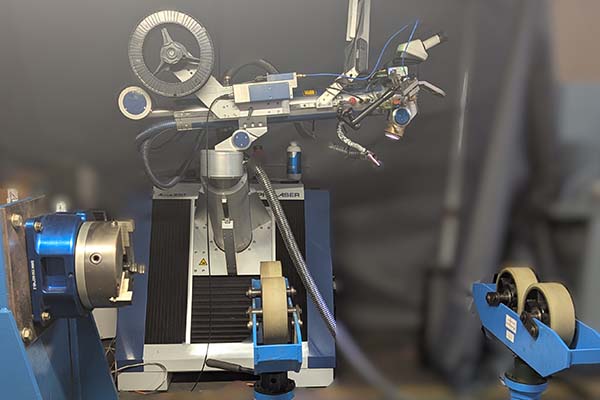

Laser Welding

Horsburgh & Scott provides expert in-house laser welding of shafts and housing bores to ensure precise, high-quality repairs and customizations that minimize downtime and maximize performance.

In-house Laser Welding for Unmatched Performance

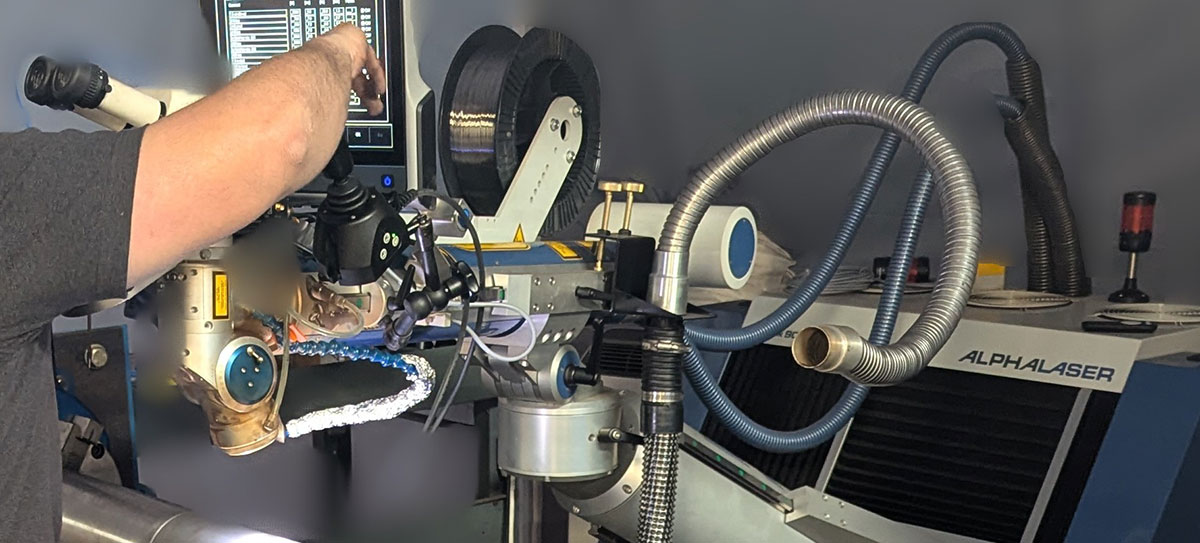

Horsburgh & Scott’s state-of-the-art laser welding technology ensures your shaft journals are welded with precision and built to last. By applying focused, localized heat, we minimize distortion and preserve exact dimensional integrity, ensuring optimal performance, even in the most demanding environments.

Our precision laser welding provides durability and superior fatigue resistance to withstand repeated cyclic loading, ensuring long-lasting joint integrity that extends the life of your equipment. Whether your equipment is powering a steel mill, mining operation, or petrochemical plant, our welded components are designed to handle your toughest challenges.

SOLUTIONS FOR:

- Housing bores

- Shaft bridge journal reclamation

- Seal journal reclamation

- New shafting provides superior wear characteristics on seal journals

ENVIRONMENTALY FRIENDLY

- No chemicals are utilized in the laser welding process

- No overspray contamination concerns

- Great replacement option for chrome (with many alternative overlay options available)

Find Sales Rep or call (216)431-3900

Advantages

- Minimal heat distortion for better dimensional accuracy

- Seamless and precision welds for enhanced durability

- Stronger joint integrity for improved load-bearing capacity

- Consistent weld quality with reduced post-processing requirements

- Extended service life with superior resistance to wear and fatigue

- Rapid execution verses compared to size limitation as common with other coating processes.